Why is forced ventilation of the crankshaft necessary? What are the benefits of forced ventilation for the crankcase?

Release time:

2023-04-19

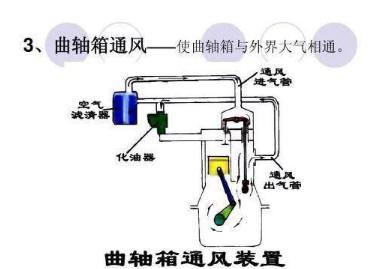

When the engine is working, combustion occurs with the high-pressure combustible mixture inside, and some gas will leak into the crankcase through the gaps between the piston assembly and the cylinder.

When the engine is working, combustion occurs with high-pressure combustible gas inside. There will be some leakage of gas through the gaps between the piston assembly and the cylinder into the crankcase, causing blow-by. The components of blow-by include fuel vapor and exhaust gas, which can dilute the engine oil, reducing its performance and accelerating oxidation and deterioration. Water vapor condensing in the oil can also form sludge, blocking oil passages. Acidic gases in exhaust mixed into the lubrication system can lead to rust, corrosion, and accelerated wear of engine components. Blow-by can also cause excessive pressure in the crankcase, damaging its sealing and leading to oil leakage and loss of lubrication for the engine.

Therefore, to prevent excessive pressure in the crankcase, extend oil service life, reduce component wear and corrosion, and prevent engine oil leaks, it is necessary to ventilate the crankcase. Additionally, to meet increasingly stringent emission requirements and improve economic performance during automotive engine design processes, crankcase ventilation design must also be included.

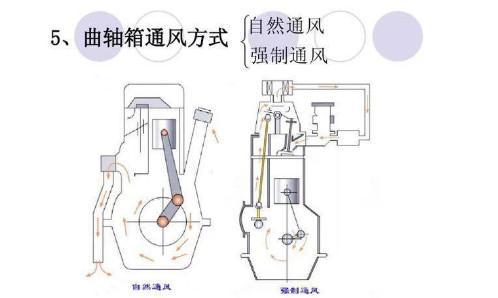

However, there are several methods for crankcase ventilation. One method is called natural ventilation. Natural ventilation involves setting up a ventilation pipe above the crankcase with an air filter; when pressure inside the crankcase increases, gases leaking into it are expelled through this pipe.

The second method is what we call forced ventilation. Forced ventilation directs mixed gases from inside the crankcase through connecting pipes to an appropriate position in the intake manifold for re-combustion in the cylinders. This not only reduces exhaust pollution but also improves engine efficiency. Currently, gasoline engines used in vehicles adopt forced ventilation measures; diesel engines are gradually adopting forced ventilation as well. Forced ventilation can be divided into open type and closed type.

Open-type forced crankcase ventilation generates a larger amount of blow-by when the engine operates at full load at low speed; however, the flow control valve's opening decreases. Excessive blow-by mixed gas will disperse into the atmosphere through an open vent cover with a purification rate of only about seventy-five percent.

Closed-type forced crankcase ventilation devices can completely control emissions from the crankcase while achieving full venting to prevent sludge and other harmful substances from accumulating, thereby reducing engine failures and wear.

Closed-type forced crankcase ventilation devices are a necessary design for gasoline engines to meet emission regulations.

Latest News