What does the wear of the crankshaft journal refer to? What are the characteristics of its wear?

Release time:

2022-09-22

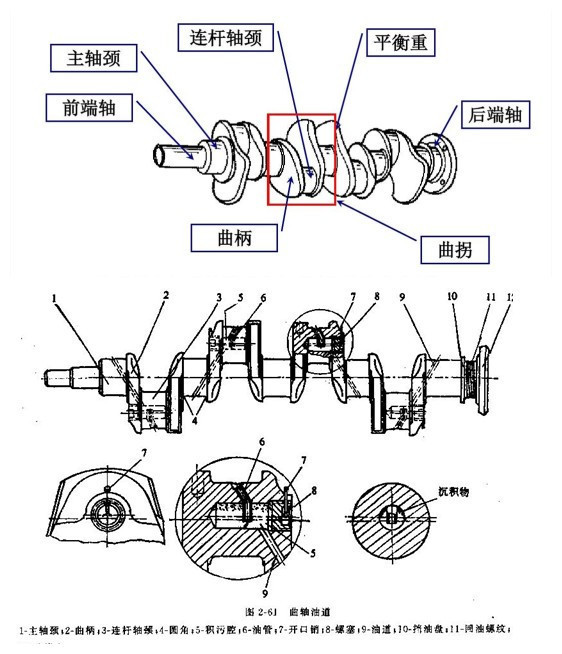

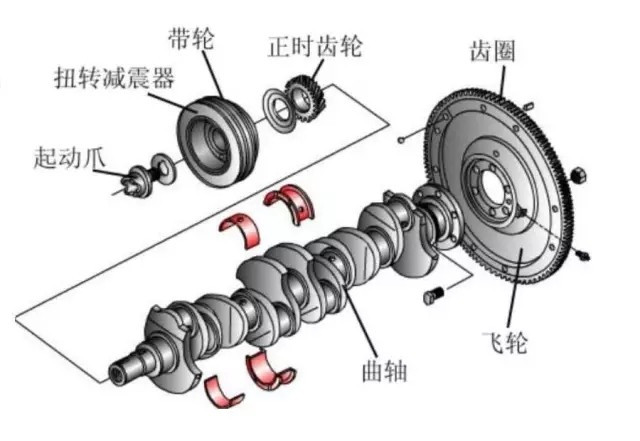

The function of the crankshaft is to convert the gas pressure transmitted by the piston-connecting rod assembly into torque for external output, and to drive the valve mechanism and other auxiliary devices. It is mostly made of high-quality medium carbon steel, medium alloy carbon steel, or ductile iron. The structure of the crankshaft includes the front end shaft, main journal, connecting rod journal, crank, balance weight, rear end shaft, etc., and there are oil passages running through the main journal, crank, and connecting rod journal to lubricate them. Due to various forces acting on it during use, there will be a certain amount of wear, and different parts have different wear characteristics.

The wear characteristics of the main journal and main bearing should be uniform in axial wear; however, radial wear is uneven and may exhibit slight ovality. Since the middle journal often bears greater loads, its wear is usually more significant than that at both ends. The radial wear of the main bearing corresponds to that of the main journal; the maximum wear occurs at the lower bearing, with more wear in the middle bearing than at both ends.

The wear characteristics of the connecting rod journal and connecting rod bearing show that radial wear is uneven with greater wear on the inner side. Uneven wear causes a certain oval shape along the radial direction of the connecting rod journal while axial wear is generally uniform. Connecting rods with an asymmetric big-end structure experience conical shape after wearing due to uneven load distribution on their connecting rod journals; similarly, if a connecting rod with a symmetric big-end structure bends, it will also result in similar consequences.

Latest News